Professional API 650 Welding Inspection Methods for Project Accuracy

Comprehending the Relevance of Welding Evaluation in Quality Guarantee Processes

Welding examination is a necessary component of quality control in building and construction and production. It guarantees that welds comply with well established standards, which is important for architectural stability. Various assessment methods, from aesthetic to ultrasonic screening, assistance recognize defects early. This positive technique not just avoids costly repairs yet additionally improves safety. Understanding the subtleties of welding examination can disclose its wider effects for market compliance and credibility. API 650 Welding Inspection. What lies beneath the surface area of these practices?

The Duty of Welding Examination in Quality Assurance

While welding is a crucial process in different industries, its high quality and stability pivot considerably on efficient examination methods. Welding evaluation works as a safeguard, ensuring that welds satisfy recognized requirements and specs. This procedure not only determines issues however likewise evaluates the overall handiwork, consequently contributing to the safety and security and longevity of bonded frameworks. Examinations are essential to quality guarantee, as they aid prevent costly failures and keep conformity with industry laws. By employing knowledgeable assessors, companies can improve their operational efficiency and maintain their reputations. In addition, the insights got from inspections can educate continual renovation, resulting in far better methodologies and training for welders. Inevitably, welding evaluation serves as an important web link in the quality control chain, guaranteeing that every joint is capable and dependable of holding up against the roughness of its designated application. This diligence is important for the stability of facilities and the safety and security of end customers.

Sorts Of Welding Inspections

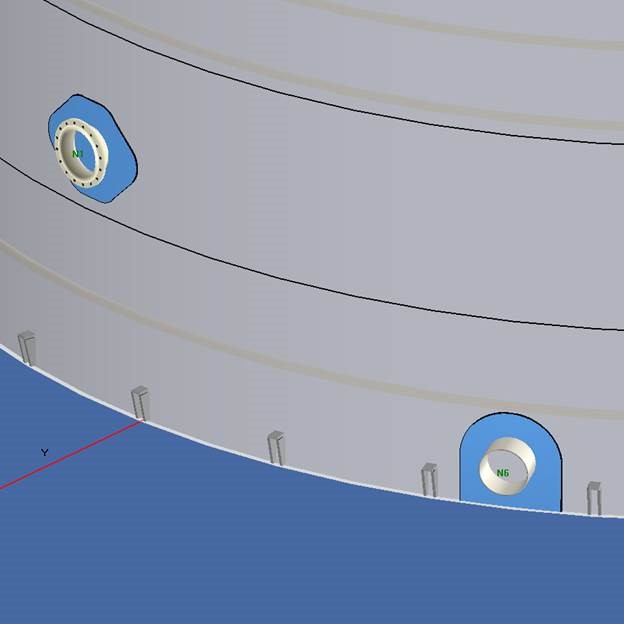

Welding inspections encompass a variety of approaches made to review the high quality and stability of welds. These examinations are important in making certain compliance with industry requirements and specifications. Typical types of welding assessments consist of aesthetic examination, which permits for immediate recognition of surface abnormalities; ultrasonic testing, which utilizes high-frequency acoustic waves to detect internal defects; and radiographic screening, utilizing X-rays or gamma rays to expose weld stability under the surface area (API 650 Welding Inspection). Furthermore, magnetic fragment testing is utilized to recognize surface area and near-surface interruptions in ferromagnetic materials, while dye penetrant screening offers an approach for disclosing surface-breaking problems. Each sort of inspection offers a details function, adding to the total quality guarantee procedure. By utilizing a mix of these methods, assessors can give a thorough evaluation of welding top quality, inevitably making certain the safety and security and reliability of bonded structures

Typical Flaws Found in Welding

A variety of usual problems can take place throughout the welding procedure, affecting the integrity and efficiency of bonded structures. These flaws include porosity, which entails trapped gas pockets within the weld, deteriorating its stamina. Cracks might likewise develop because of quick cooling or improper joint layout, bring about possible failure under stress. Incomplete fusion occurs when there is not enough melting of the base metal, leading to weak bonds. An additional issue, undercutting, involves the removal of base metal along the i thought about this weld edge, creating a significant architectural weak point. Furthermore, extreme spatter can impact the look and require further cleaning or repair service. Misalignment can lead to uneven weld grains, compromising the general quality. Determining these issues early through correct evaluation strategies is vital to assure the dependability and safety and security of welded components, inevitably guarding the efficiency of the entire structure.

Benefits of Regular Welding Inspections

Regular inspections play a significant function in preserving the top quality and security of bonded structures, specifically taking into account the typical problems formerly detailed. These assessments give an opportunity to recognize and correct concerns prior to they rise into severe problems, ensuring structural integrity. By identifying flaws early, companies can reduce fixing costs and stay clear of prospective job content hold-ups.

In addition, normal welding assessments improve conformity with industry standards and laws, fostering trust amongst stakeholders. This adherence not just protects the business's credibility yet likewise contributes to improved security for employees and the general public.

Furthermore, constant inspections assist in much better training and skill growth for welders, as responses from evaluations can direct enhancements. Inevitably, the advantages of regular welding examinations expand past immediate quality control, promoting long-term operational effectiveness and dependability in bonded frameworks.

Finest Practices for Effective Welding Evaluation

Implementing finest techniques in welding examination is crucial for ensuring the greatest requirements of quality and safety. Inspectors need to be effectively trained and certified, possessing a complete understanding of welding techniques and materials. Using sophisticated inspection modern technologies, such as ultrasonic testing and radiography, boosts the detection of problems that might not show up to the naked eye. Developing a clear examination plan, outlining the standards and frequency of evaluations, guarantees uniformity and thoroughness.

Documenting all findings carefully is essential for traceability and responsibility. Normal calibration of inspection equipment assures precision, while maintaining a clean and well organized workspace minimizes the danger of contamination. In addition, fostering open communication among group members helps with the sharing of insights and promotes a society of top quality. By sticking to these finest methods, organizations can notably boost their welding quality control processes, ultimately bring about more secure and a lot more reputable products.

Often Asked Inquiries

What Qualifications Are Needed for a Welding Assessor?

A welding assessor typically needs certification from acknowledged companies, such as the American Welding Culture (AWS) or the International Institute of Welding (IIW), in addition to appropriate experience and understanding in welding procedures and high quality standards.

Exactly How Typically Should Welding Inspections Be Carried Out?

Welding examinations ought to be done regularly, usually at different job phases, including before, throughout, and after welding processes - API 650 Welding Inspection. The regularity commonly relies on job requirements, regulatory my website requirements, and the intricacy of the welds involved

What Are the Expenses Associated With Welding Inspections?

The expenses related to welding assessments differ extensively, normally ranging from a couple of hundred to numerous thousand bucks, relying on variables like assessment kind, job size, and place, influencing general task budgets and timelines.

Can Welding Inspections Be Carried Out From Another Location?

Yes, welding evaluations can be conducted remotely making use of innovative modern technologies such as drones, cameras, and ultrasonic screening. These techniques enable examiners to analyze weld stability without being physically present, improving performance and security in different settings.

Just How Do Assessment Outcomes Effect Project Timelines?

Evaluation results can significantly affect project timelines by determining problems early, leading to required rework or adjustments. Delays may happen if evaluations expose issues requiring resolution, inevitably affecting total project completion and spending plan adherence.

Welding evaluations incorporate an array of methods developed to assess the quality and honesty of welds. Common types of welding assessments include aesthetic inspection, which permits for instant identification of surface irregularities; ultrasonic screening, which uses high-frequency sound waves to find interior imperfections; and radiographic screening, using X-rays or gamma rays to disclose weld stability underneath the surface area. Consistent evaluations facilitate far better training and ability advancement for welders, as feedback from evaluations can lead improvements. Carrying out finest practices in welding evaluation is crucial for assuring the highest standards of high quality and safety and security. Welding examinations must be done on a regular basis, generally at various task stages, consisting of prior to, throughout, and after welding processes.